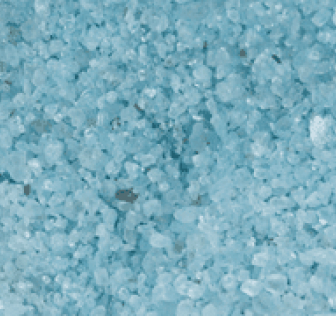

Calcined Clays

Calcined Clays are often used as the standard topcoat material that can absorb moisture out of the infield mix, helping to regulate the safety of infields while also smoothing the surface for premium ball roll. Calcined products are made of montmorillonite clays that have been fired at 1500F to expand the material, creating greater porosity. Calcined clays are often used during cool and rainy spring conditions, but most field managers will use them all year in some percentage of their topcoat. Calcined clay is available in several sizes that vary based upon the level of use of the facility. Finer gradient products are preferred by professional end-users, while high schools and rec level organizations typically get more bang for their buck by using slightly larger-sized materials.

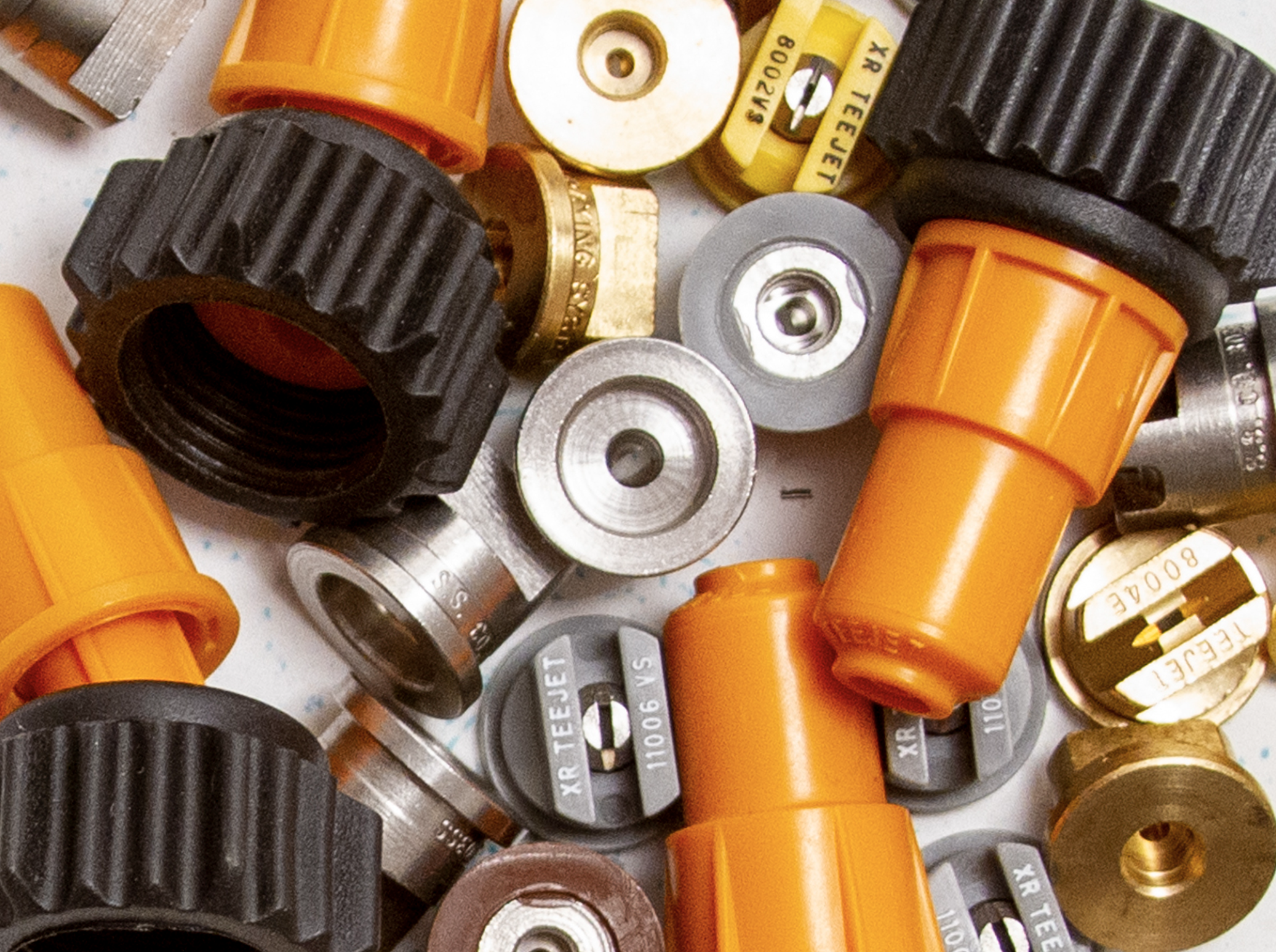

Vitrified Conditioners

Field managers use vitrified conditioners to allow water to pass through the topcoat more efficiently into the base material underneath. Unlike calcined clays, which are fired clays, vitrified conditioners are expanded shale that has been fired at even higher temperatures. Though field managers often add a modest amount of vitrified conditioner in the spring, these products are best recognized as warm weather products and are used most abundantly during hot and dry summer conditions. Vitrified conditioners are heavier and more durable products that break down at a slower rate and don’t blow around as much in windy conditions. In general, the sizing of these products mimics the same use structure as the calcined clays for maximum cost-effectiveness.

Drying Agents

Drying agents are super fine clay dust products that can absorb a maximum amount of water beyond the limit of traditional infield products. These are excellent products to help soak up puddles or get field managers through rainy games but should always be used with caution. These materials should be removed after the game or the following day from areas applied, as they can bind up pore space in infield mixes and cause a hardening effect once dry.

Breakdown

This brings me to my final point. All infield materials have a finite life span. Calcined clays and vitrified conditioners break down over time from friction caused by dragging fields. They also can blow away during windy, dry periods.

Field managers should check periodically to see that their conditioner levels remain constant throughout their season. Routine additions help freshen the surface while also replacing what has broken down or blown off.

Keep in mind that as these clays/conditioners break down into finer particles, they should be periodically removed to avoid binding up the surface of your infield. I recommend twice per year to remove fines, but this will be dependent upon the level of play, the amount of play, and the amount the field is dragged. Many field managers strip fields and store these products when out of season to lessen migration of materials that often contribute to lip development over time.