Each spring, we consistently get questions about mixing multiple plant health care products into the tank in order to save on labor and multiple applications. Tank mixing multiple products into a spray solution is an especially valuable tool to utilize due to labor shortages.

But, how do you know what will mix and what will not mix well? Performing a “jar” test should always be done if there are any questions or unknowns about the products you intend to mix in the sprayer. The purpose of a jar test is to recreate your spray solution in a much smaller volume container in order to test product compatibility. It is much better to have a small pint-size jar of incompatible product versus a 300-gallon spray tank that is difficult to clean. Your investment of time to do a jar test will be minuscule in comparison to cleaning out a large spray tank and disposing of the material. Incompatible materials can cause ingredients to precipitate out of solution, can cause the tank contents to turn into mayonnaise-like consistency, or create a super foamy substance. Just like your science class days long ago, chemical reactions can be wild and surprising. Below are some basic instructions/tips for performing a jar test.

Jar Test for tank mixing:

- Clear jars work best for observation

- Read your labels first for information. Most labels discuss tank mixing and sometimes have compatible products mentioned.

- Always use the standardized mixing order (listed below)

- Use the same mixing proportions as you plan to use in your spray tank

- With a lid on the jar, shake well in order to incorporate the products together

- Let stand for 15 minutes or longer and observe

- If no capability issues are found, your tank mix physically should work. However, be cautious about how these chemicals combine and their effect on a sprayed target. Phytotoxicity can be an issue even if the chemicals appear to be compatible.

What you may see:

- If you see separation of liquids (for example oil/water), this is incompatible

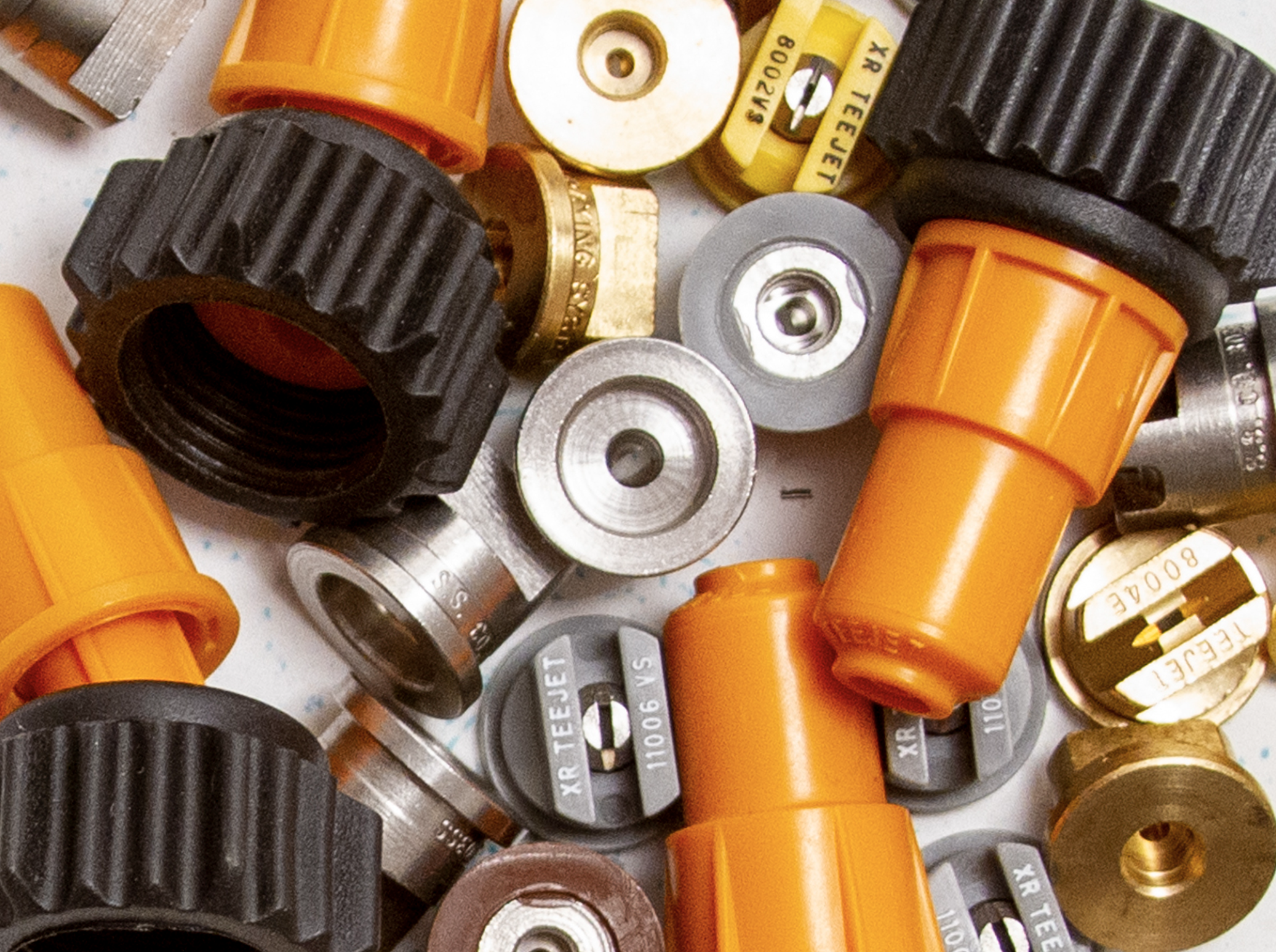

- If the consistency or viscosity of the mix thickens, do not use it. You will have trouble running this through your pump, tubing, filters, nozzles, etc.

- If large chunks or globs fall out of the solution and sink to the bottom, do not use it.

- If very small particles settle to the bottom, you may be able to use this mix if you have good spray tank agitation. Sufficient agitation will keep suspended products in suspension.

Loading tank/mixing order:

- Fill the tank roughly halfway with the carrier (usually water)

- Start tank agitation prior to adding products

- Add products in order by their formulation:

- Water-soluble packets (I typically mix these separately in a 5-gallon bucket, making a slurry in order to assure the bags have dissolved as they are designed)

- Dry formulations

- Ammonium Sulfate (AMS)

- Compatibility agents and defoamers

- Dispersed liquid formulations

- Liquid anti-drift agents.

- Other liquid formulations

- Adjuvants

- Liquid fertilizers

- Adjust pH with a buffering solution if necessary

- Observe the mixture in the tank while agitating. If all looks good, fill the tank to the desired volume and you are now ready to spray.

Tank mixing is a great way to increase the effectiveness of your weed control program or even tackle multiple plant health problems at the same time. However, please be cautious; I have found by getting greedy and adding too many things in the tank, phytotoxicity becomes more prevalent. Always use the required PPE when working with chemicals and read the label. This is chemistry after all, and if misused, problems may occur.

Universities and manufacturers often have literature on tank mixing procedures. The above info is based on the publication titled “Avoid Tank Mixing Errors: A Guide to Applying the Principles of Compatibility and Mixing Sequence” published by Purdue University which can be found online.

Feel free to contact your Advanced Turf Rep for their experiences and ideas regarding tank mixing. We are here to help!